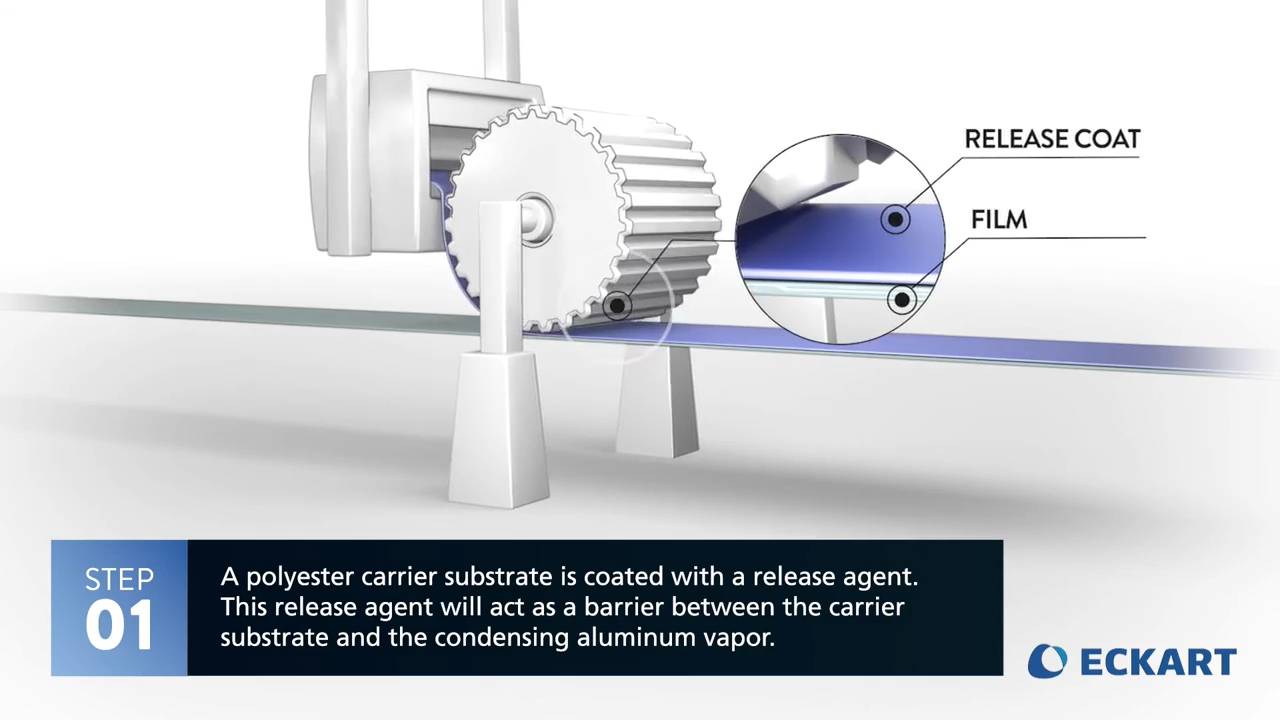

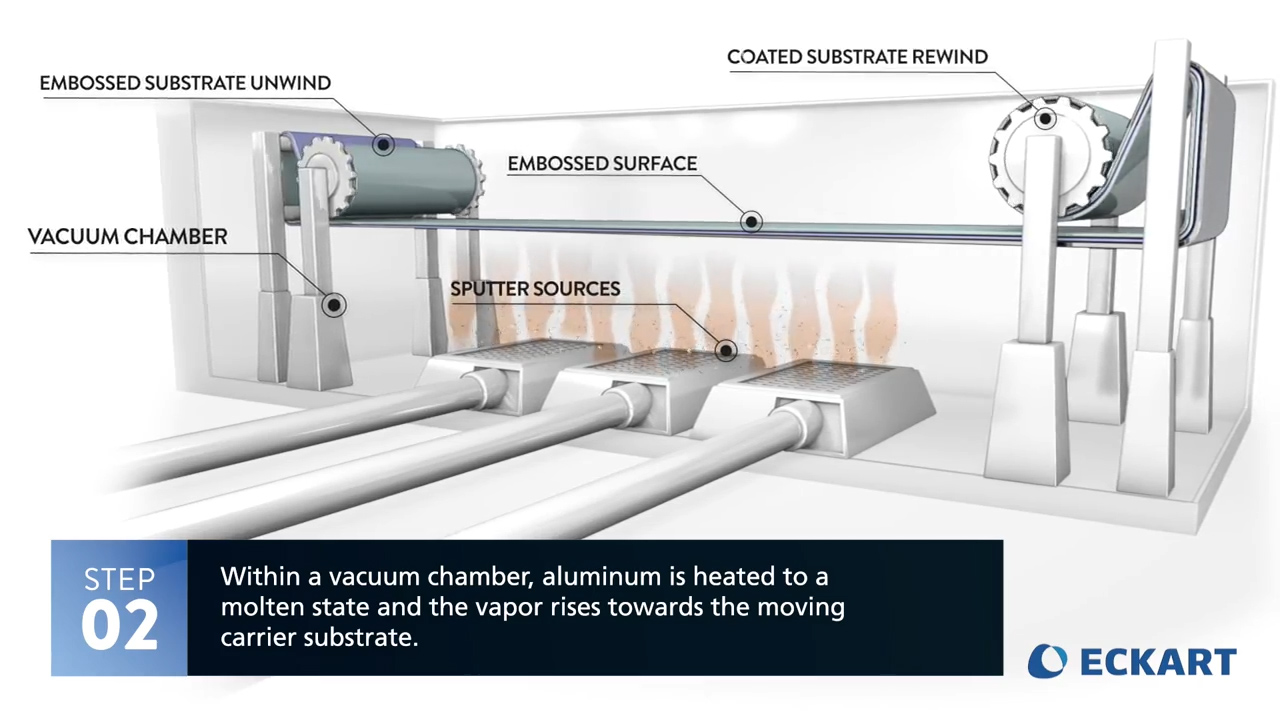

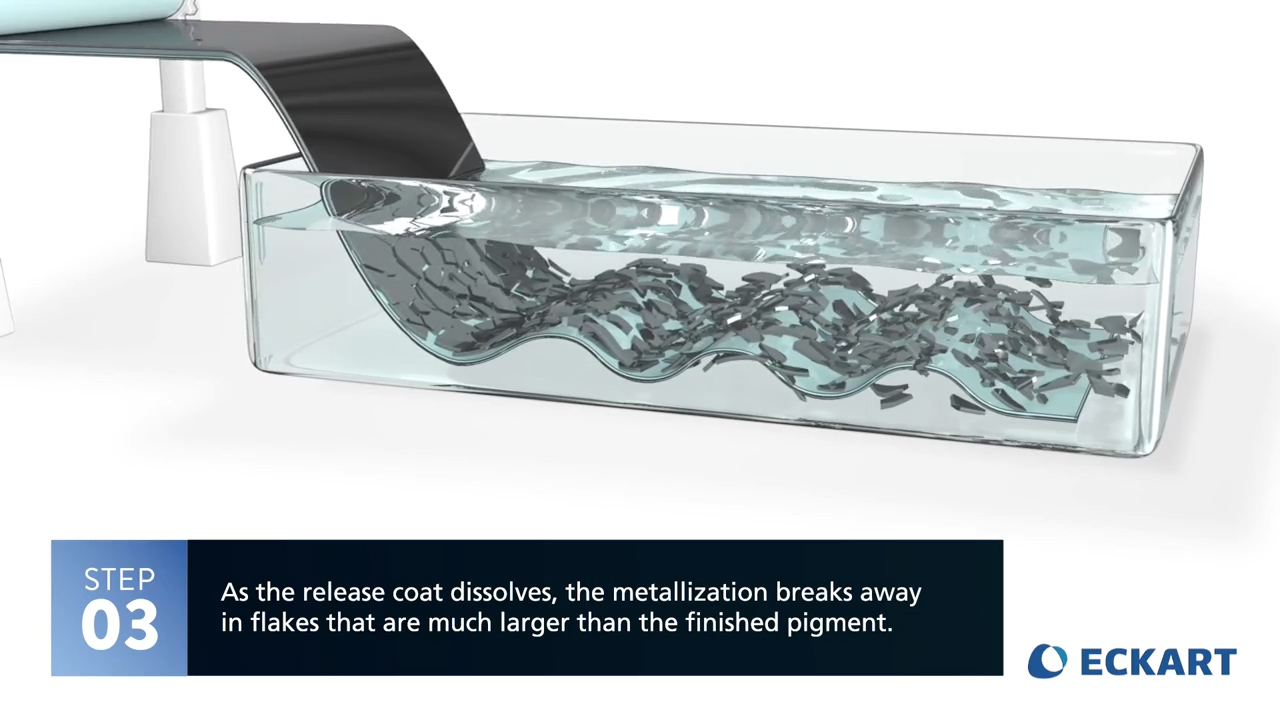

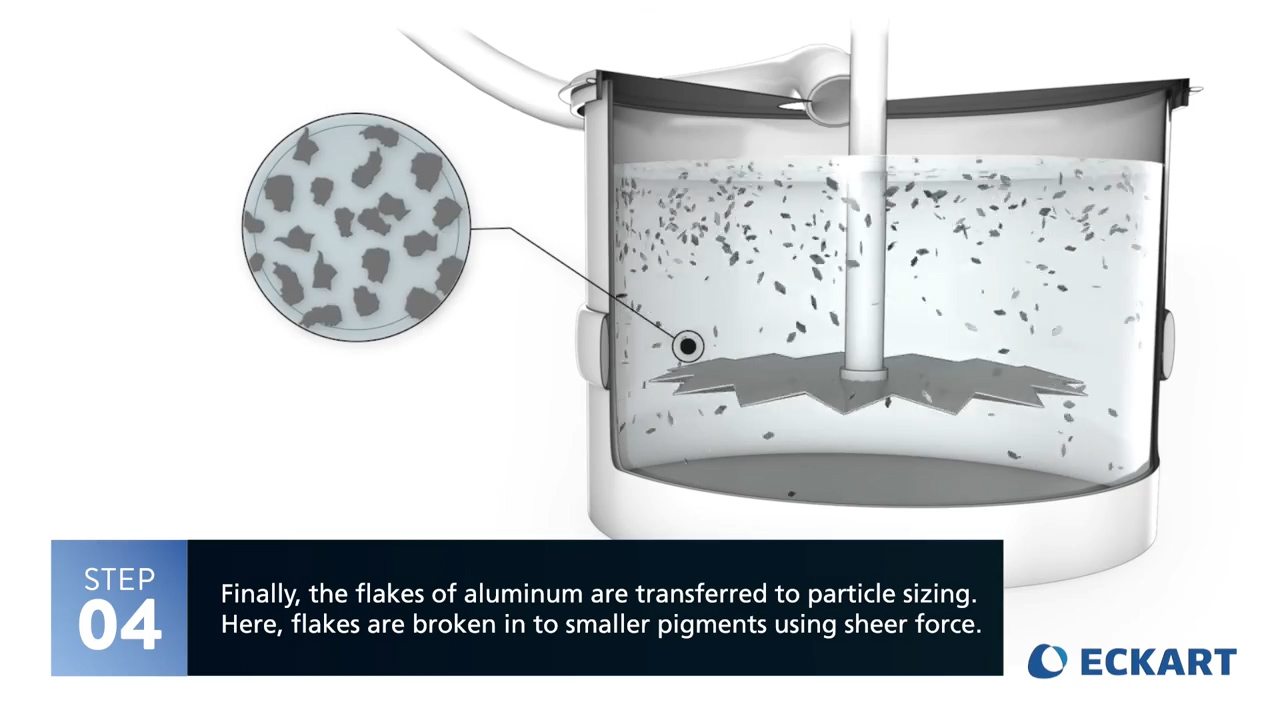

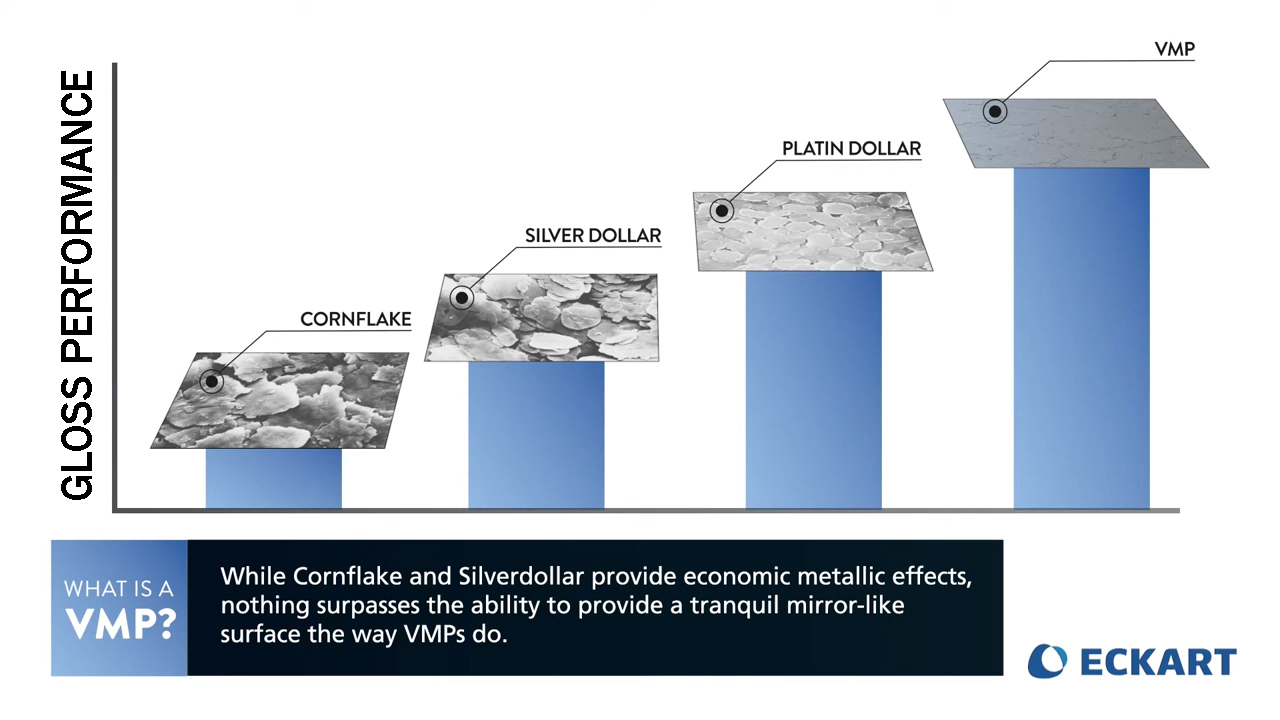

All vacuum metallized pigments are ultra-brilliant aluminum pigment dispersions designed to create the highest level of reflectance in solvent borne coatings and inks, covering the complete range of effects: ultra-dark to light color shades, soft to intensive chrome-like effects, brilliant to highly-brilliant.