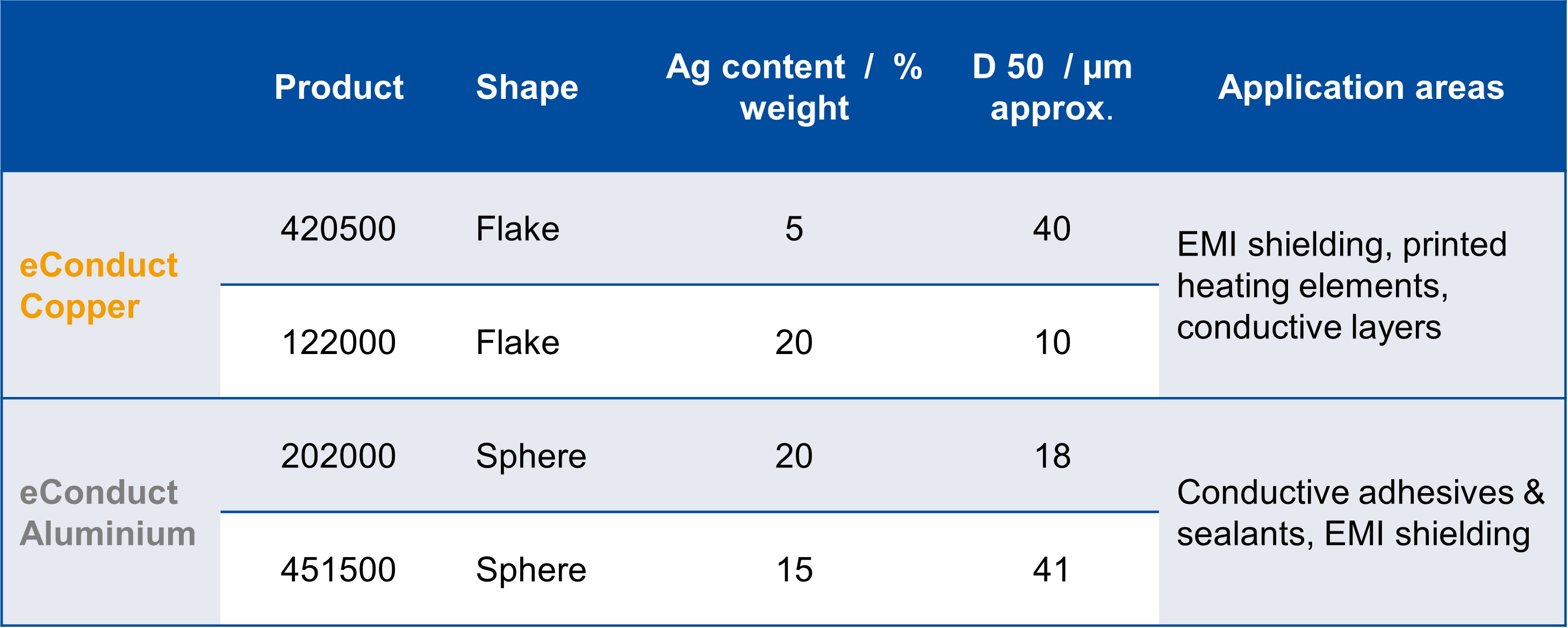

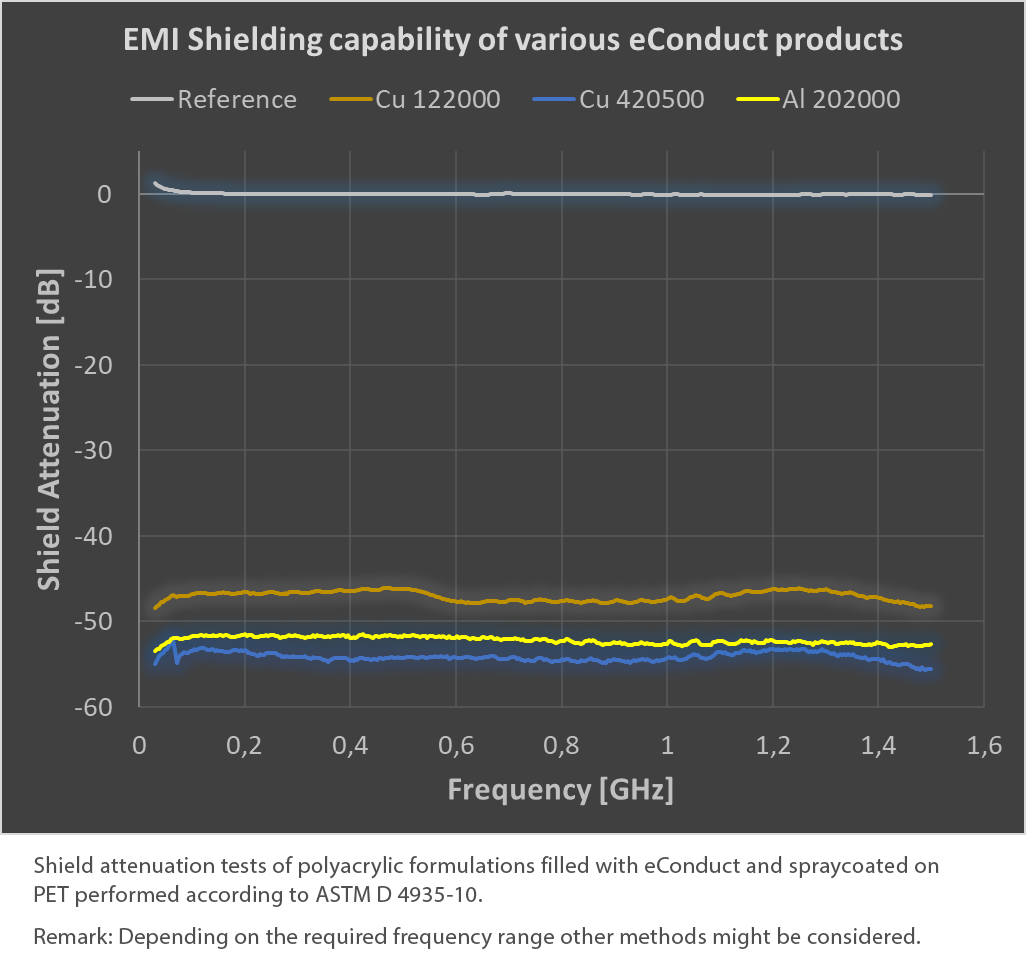

The combination of the high electrical conductivity of the silver shell with a pigment core consisting of a comparatively inexpensive material allows us to provide a hybrid system with balanced cost-performance ratio.

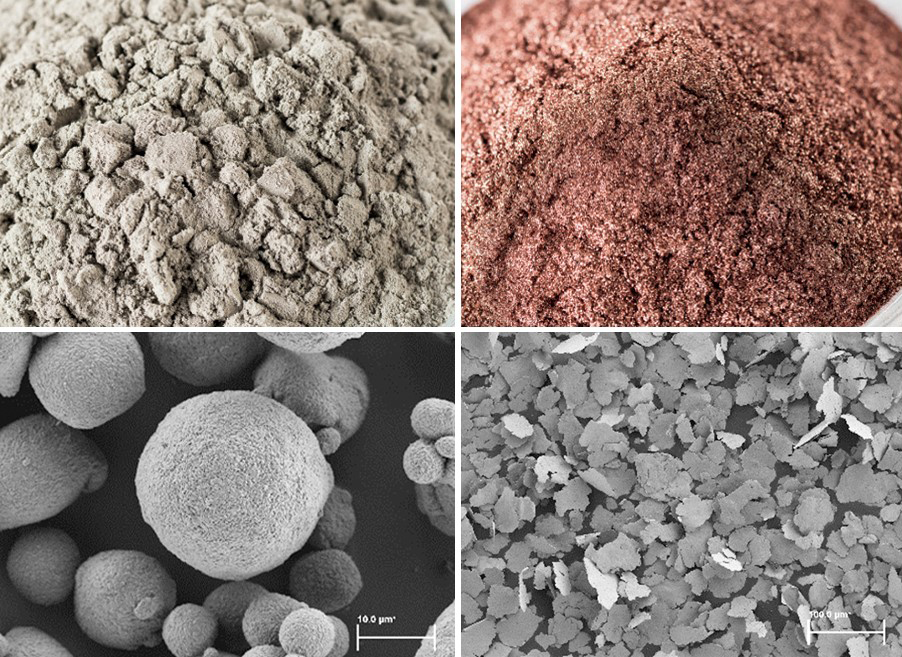

The eConduct product range from ECKART contains either flake shaped or spherical silver-coated glass, aluminum or copper substrates, which are provided in powder form.